- Have any questions ? +91-9004329048

- contact@pigeonis.in

Renewable Energy Solutions

UAV Drone Wind Turbine Inspection in India

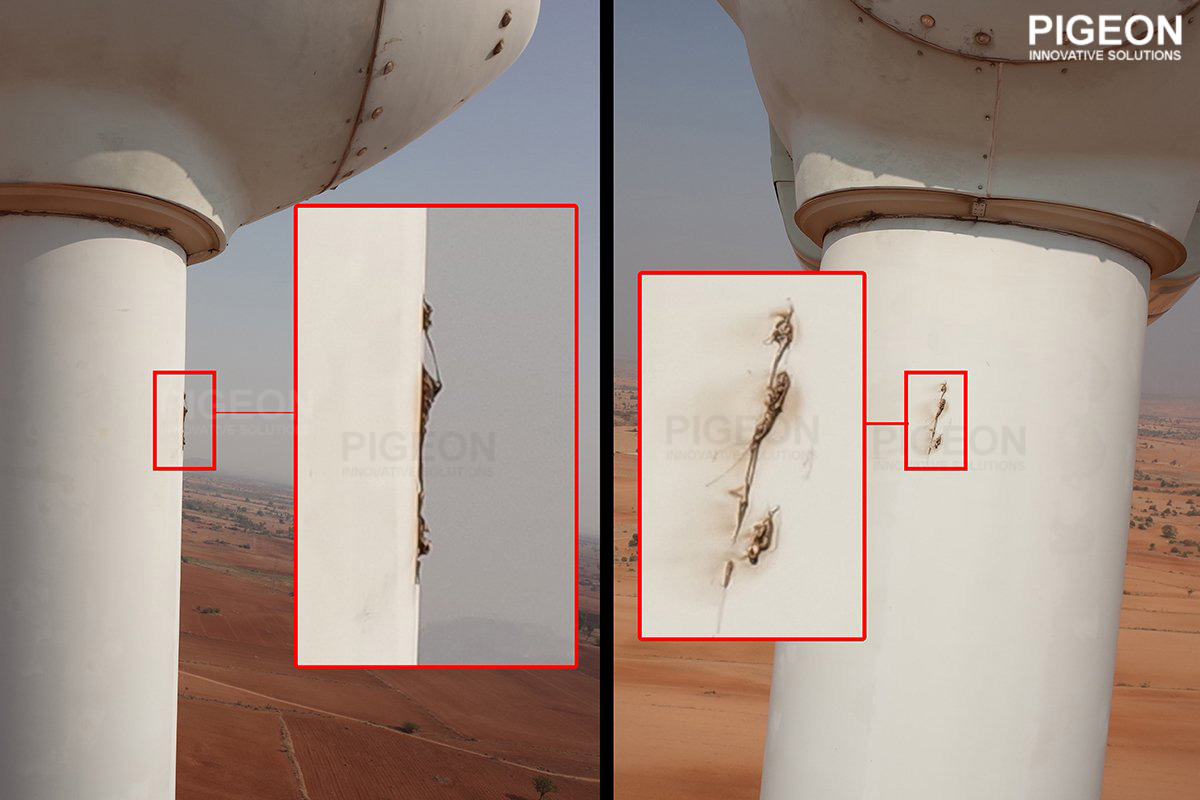

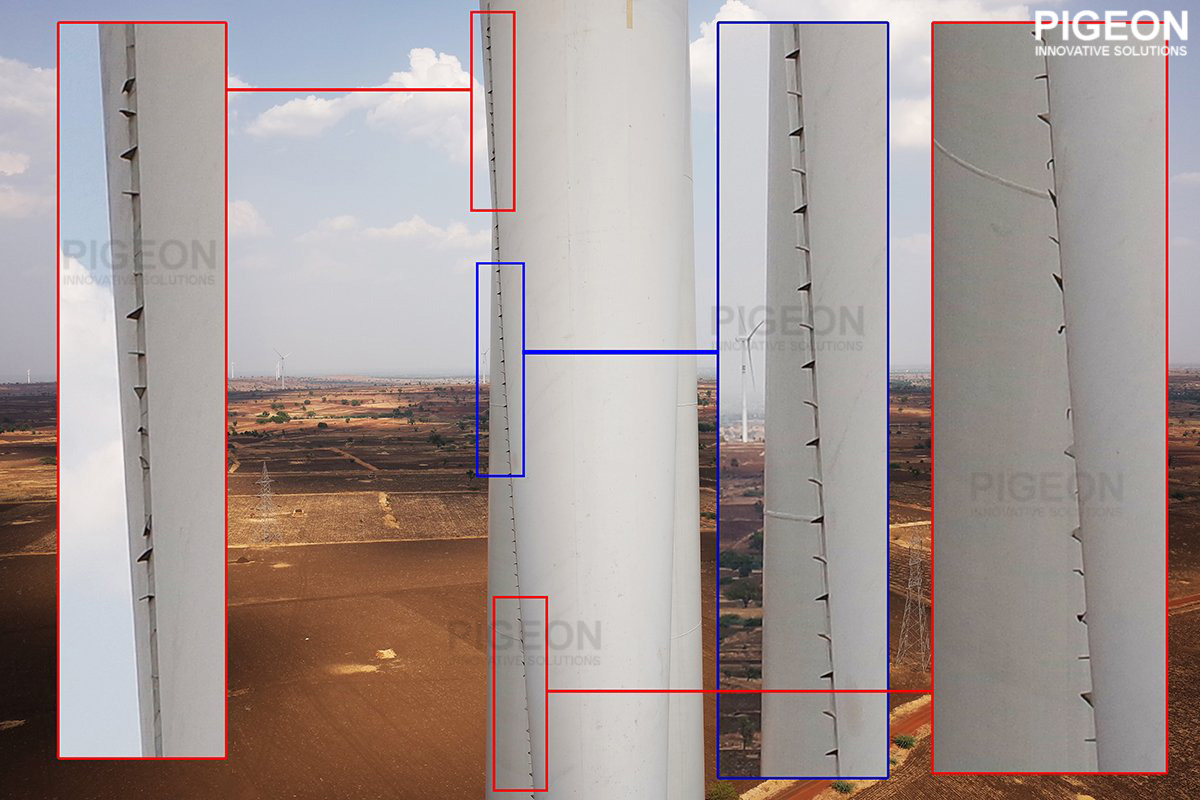

Wind Turbine Inspection, a role traditionally accomplished visually from the ground with Binoculars/Telephoto lenses or a relatively complicated rope/platform access. We, at Pigeonis use Unmanned Aerial Vehicle(UAV)/Drones with a streamlined operating procedure, not only limited to inspection of the blades but also of the tower and nacelle, resulting in an easy, economic and safe inspection with a reduced downtime (<60mins per turbine)

Drones are equipped with customized sensors, digital cameras, Infrared/Thermal imaging sensors to collect high-quality data from the most optimal perspective after a survey of various viewing angles. The collected data can further be scrutinized accurately by our in-house wind turbine experts and anomalies identified can be inspected accordingly before providing a complete feedback and a summarized report.

(Wind Turbine Inspections involve identification of defects such as: Dents, Cracks, Delamination, Gel-coat degradation, Paint peel-off, Lightning Strike damage, Lightning Receptor damage, Vortex Generator damage, Fiber Wrinkles, Manufacturing anomalies, installation damage, etc)

Regularly scheduled inspections can help in understanding the condition of your assets, improve maintenance cycle planning, warranty claims, Insurance, improve overall efficiency and life of blades, optimize manpower, identify issues early-on and schedule maintenance to prevent unnecessary costs and catastrophic turbine failures in the future.

Wind Turbine Inspections are known to be time-consuming, and we, at Pigeonis with highly experienced team are dedicated to provide most advanced solutions in a timely manner.

We also conduct land survey for initial wind mast feasibility study, providing contour lines, digital elevation model, orthophoto, 3D models. Aerial survey is very helpful, as it consumes less time and also provides 10x clear image than Google Earth.

Solar panel inspection using drones in India

Solar panel inspection forms an important part of quality control and periodic maintenance schedules. Using Unmanned Aerial Vehicle(UAV)/Drone technology proves an efficient method of validating installations and helps maintain maximum operational output from aging infrastructures. This enables operators to substantially reduce the time spent inspecting solar fields and instead target their resources and finances towards deficient panels only.

Photovoltaic panels emit a certain amount of heat and due to prolonged exposure, defective panels give off more heat than optimally functioning panels. This difference in temperature can be detected using an infrared thermal imaging camera installed on our drones.

(Drone Solar Panel Inspection involve identification of defects such as: Hotspots, Micro cracking, Complete panel failure, Pollution and mould build up, Potential damage after storms, Defective Cells, False Plantation Growth, etc)

Our reports can be used for warranty and certification purposes, Insurance, maintenance contracts or presented to the panel manufacturer.

*Research and Development Stage

We also conduct land survey for initial planning of solar farm, providing cut/fill volume estimation for flattening the land, contour lines, digital elevation model, orthophoto, 3D models. Drone survey is very helpful, as it is quick and also produces actual view of the land which is not possible in traditional survey techniques.